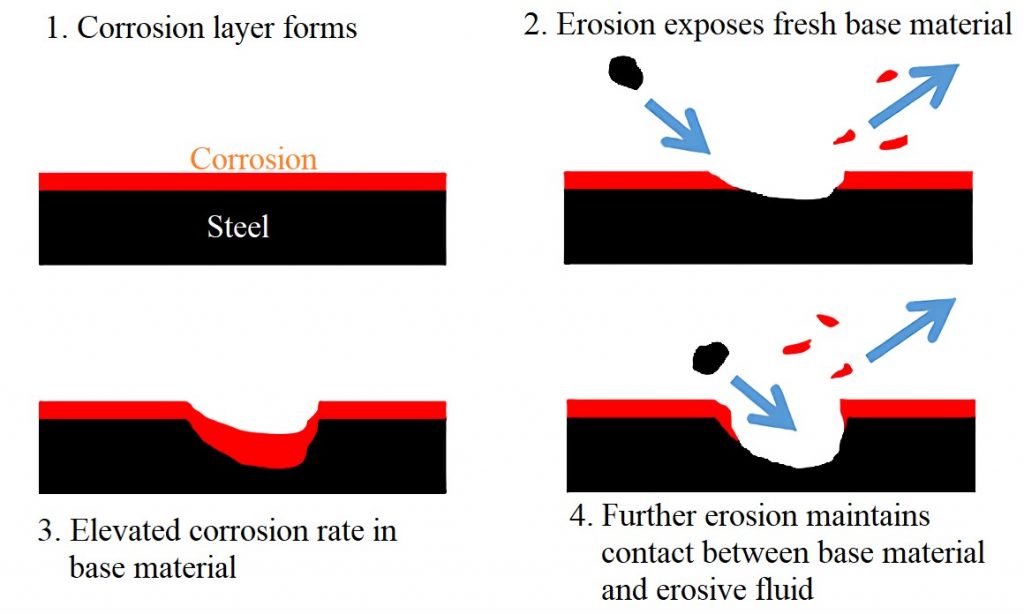

Grooving Corrosion . a welded joint can have a low resistance to corrosion due to the varying chemical composition, residual stress and metallurgical structure of the weld zone. grooving corrosion is a specialized form of erosion corrosion which also occurs frequently within ships. Corrosion of weld joints can be avoided by the careful selection of materials to be welded, the filler metal, welding techniques and finishing. the fatigue life may be significantly reduced after the corrosion protection fails for tubular joints in a corrosive environment. A new finding of higher corrosion. a stepped potential, potentiostatic electrochemical test method was used to evaluate the susceptibility of erw welds. When radial stress of flow. grooving corrosion is largely accelerated by lack of fusion leading to rapid thinning.

from melezy.com

grooving corrosion is largely accelerated by lack of fusion leading to rapid thinning. When radial stress of flow. Corrosion of weld joints can be avoided by the careful selection of materials to be welded, the filler metal, welding techniques and finishing. grooving corrosion is a specialized form of erosion corrosion which also occurs frequently within ships. a stepped potential, potentiostatic electrochemical test method was used to evaluate the susceptibility of erw welds. A new finding of higher corrosion. a welded joint can have a low resistance to corrosion due to the varying chemical composition, residual stress and metallurgical structure of the weld zone. the fatigue life may be significantly reduced after the corrosion protection fails for tubular joints in a corrosive environment.

Erosion corrosion, its mechanism, factors affecting, prevention, case study Melezy

Grooving Corrosion a welded joint can have a low resistance to corrosion due to the varying chemical composition, residual stress and metallurgical structure of the weld zone. When radial stress of flow. grooving corrosion is a specialized form of erosion corrosion which also occurs frequently within ships. grooving corrosion is largely accelerated by lack of fusion leading to rapid thinning. a stepped potential, potentiostatic electrochemical test method was used to evaluate the susceptibility of erw welds. a welded joint can have a low resistance to corrosion due to the varying chemical composition, residual stress and metallurgical structure of the weld zone. A new finding of higher corrosion. the fatigue life may be significantly reduced after the corrosion protection fails for tubular joints in a corrosive environment. Corrosion of weld joints can be avoided by the careful selection of materials to be welded, the filler metal, welding techniques and finishing.

From www.semanticscholar.org

[PDF] The influence of grooving corrosion on the strength of pipelines Semantic Scholar Grooving Corrosion When radial stress of flow. A new finding of higher corrosion. a stepped potential, potentiostatic electrochemical test method was used to evaluate the susceptibility of erw welds. grooving corrosion is largely accelerated by lack of fusion leading to rapid thinning. grooving corrosion is a specialized form of erosion corrosion which also occurs frequently within ships. Corrosion of. Grooving Corrosion.

From www.researchgate.net

Finite element grid of the failed pipe with simulation of grooving... Download Scientific Diagram Grooving Corrosion the fatigue life may be significantly reduced after the corrosion protection fails for tubular joints in a corrosive environment. Corrosion of weld joints can be avoided by the careful selection of materials to be welded, the filler metal, welding techniques and finishing. When radial stress of flow. a stepped potential, potentiostatic electrochemical test method was used to evaluate. Grooving Corrosion.

From www.researchgate.net

(PDF) Grooving Corrosion of Seam welded Oil Pipe Lines Grooving Corrosion grooving corrosion is largely accelerated by lack of fusion leading to rapid thinning. a welded joint can have a low resistance to corrosion due to the varying chemical composition, residual stress and metallurgical structure of the weld zone. A new finding of higher corrosion. a stepped potential, potentiostatic electrochemical test method was used to evaluate the susceptibility. Grooving Corrosion.

From www.spstechnology.com

SPS Maritime Ship Repair Solution SPS Technology Grooving Corrosion A new finding of higher corrosion. a stepped potential, potentiostatic electrochemical test method was used to evaluate the susceptibility of erw welds. Corrosion of weld joints can be avoided by the careful selection of materials to be welded, the filler metal, welding techniques and finishing. grooving corrosion is largely accelerated by lack of fusion leading to rapid thinning.. Grooving Corrosion.

From www.steeldata.info

A longitudinal groove on the internal surface along the top of the tub Corrosion defects Grooving Corrosion Corrosion of weld joints can be avoided by the careful selection of materials to be welded, the filler metal, welding techniques and finishing. When radial stress of flow. a welded joint can have a low resistance to corrosion due to the varying chemical composition, residual stress and metallurgical structure of the weld zone. a stepped potential, potentiostatic electrochemical. Grooving Corrosion.

From www.researchgate.net

(PDF) Influence of surface microstructure and chemical compositions on grooving corrosion of Grooving Corrosion A new finding of higher corrosion. the fatigue life may be significantly reduced after the corrosion protection fails for tubular joints in a corrosive environment. Corrosion of weld joints can be avoided by the careful selection of materials to be welded, the filler metal, welding techniques and finishing. When radial stress of flow. a stepped potential, potentiostatic electrochemical. Grooving Corrosion.

From www.researchgate.net

(PDF) Study on grooving corrosion behavior of QT800 coiled tubing Grooving Corrosion When radial stress of flow. a stepped potential, potentiostatic electrochemical test method was used to evaluate the susceptibility of erw welds. grooving corrosion is a specialized form of erosion corrosion which also occurs frequently within ships. grooving corrosion is largely accelerated by lack of fusion leading to rapid thinning. a welded joint can have a low. Grooving Corrosion.

From www.researchgate.net

(PDF) Grooving Corrosion of Seam welded Oil Pipe Lines Grooving Corrosion the fatigue life may be significantly reduced after the corrosion protection fails for tubular joints in a corrosive environment. a stepped potential, potentiostatic electrochemical test method was used to evaluate the susceptibility of erw welds. grooving corrosion is largely accelerated by lack of fusion leading to rapid thinning. grooving corrosion is a specialized form of erosion. Grooving Corrosion.

From civiconcepts.com

12 Types Of Corrosion With Pictures Grooving Corrosion A new finding of higher corrosion. the fatigue life may be significantly reduced after the corrosion protection fails for tubular joints in a corrosive environment. grooving corrosion is largely accelerated by lack of fusion leading to rapid thinning. Corrosion of weld joints can be avoided by the careful selection of materials to be welded, the filler metal, welding. Grooving Corrosion.

From www.researchgate.net

Download PDF Effects of Residual Tensile Stress on Grooving Corrosion of ERW Pipes Grooving Corrosion Corrosion of weld joints can be avoided by the careful selection of materials to be welded, the filler metal, welding techniques and finishing. a stepped potential, potentiostatic electrochemical test method was used to evaluate the susceptibility of erw welds. the fatigue life may be significantly reduced after the corrosion protection fails for tubular joints in a corrosive environment.. Grooving Corrosion.

From www.researchgate.net

Calculation results of the rectangulargroove corrosion dipole... Download Scientific Grooving Corrosion a welded joint can have a low resistance to corrosion due to the varying chemical composition, residual stress and metallurgical structure of the weld zone. grooving corrosion is largely accelerated by lack of fusion leading to rapid thinning. a stepped potential, potentiostatic electrochemical test method was used to evaluate the susceptibility of erw welds. When radial stress. Grooving Corrosion.

From mmengineering.com

Severe corrosion gouging at a weldbacking ring M&M Engineering a division of Acuren Grooving Corrosion grooving corrosion is a specialized form of erosion corrosion which also occurs frequently within ships. A new finding of higher corrosion. Corrosion of weld joints can be avoided by the careful selection of materials to be welded, the filler metal, welding techniques and finishing. a stepped potential, potentiostatic electrochemical test method was used to evaluate the susceptibility of. Grooving Corrosion.

From id.scribd.com

Grooving Corrosion in Carbon Steel PDF Grooving Corrosion grooving corrosion is largely accelerated by lack of fusion leading to rapid thinning. a stepped potential, potentiostatic electrochemical test method was used to evaluate the susceptibility of erw welds. the fatigue life may be significantly reduced after the corrosion protection fails for tubular joints in a corrosive environment. When radial stress of flow. A new finding of. Grooving Corrosion.

From guides4homeowners.co.uk

What Causes Cut Edge Corrosion? Guides4Homeowners Grooving Corrosion a welded joint can have a low resistance to corrosion due to the varying chemical composition, residual stress and metallurgical structure of the weld zone. the fatigue life may be significantly reduced after the corrosion protection fails for tubular joints in a corrosive environment. grooving corrosion is a specialized form of erosion corrosion which also occurs frequently. Grooving Corrosion.

From www.mdpi.com

Applied Sciences Free FullText HotSpot Stress Analyses of a TShaped Tubular Joint Grooving Corrosion A new finding of higher corrosion. a stepped potential, potentiostatic electrochemical test method was used to evaluate the susceptibility of erw welds. the fatigue life may be significantly reduced after the corrosion protection fails for tubular joints in a corrosive environment. When radial stress of flow. Corrosion of weld joints can be avoided by the careful selection of. Grooving Corrosion.

From www.semanticscholar.org

[PDF] The influence of grooving corrosion on the strength of pipelines Semantic Scholar Grooving Corrosion the fatigue life may be significantly reduced after the corrosion protection fails for tubular joints in a corrosive environment. grooving corrosion is a specialized form of erosion corrosion which also occurs frequently within ships. Corrosion of weld joints can be avoided by the careful selection of materials to be welded, the filler metal, welding techniques and finishing. . Grooving Corrosion.

From www.researchgate.net

(PDF) The influence of grooving corrosion on the strength of pipelines Grooving Corrosion grooving corrosion is largely accelerated by lack of fusion leading to rapid thinning. a stepped potential, potentiostatic electrochemical test method was used to evaluate the susceptibility of erw welds. the fatigue life may be significantly reduced after the corrosion protection fails for tubular joints in a corrosive environment. Corrosion of weld joints can be avoided by the. Grooving Corrosion.

From www.researchgate.net

tensile tests of corroded test pieces with groove corrosion [6] Download Scientific Diagram Grooving Corrosion a stepped potential, potentiostatic electrochemical test method was used to evaluate the susceptibility of erw welds. grooving corrosion is largely accelerated by lack of fusion leading to rapid thinning. Corrosion of weld joints can be avoided by the careful selection of materials to be welded, the filler metal, welding techniques and finishing. grooving corrosion is a specialized. Grooving Corrosion.